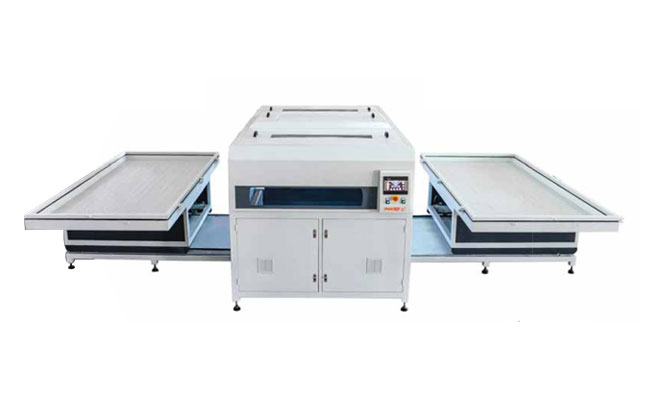

Vacuum Membrane Press

Vacuum Membrane Press

Vacuum Membrane Press

Press The Workpiece To The Required Shape

The high standard vacuum membrane press is economical that makes the job easy for vacuum forming in woodworking with flat & curved components. This press machine has been designed for precise production with moulds, equipped with an infrared heat sensor system and maintenance-free quality vacuum pumps. It can meet the demands of industrial individual requirements such as a continuous production cycle with quality features. The high-strength machine body maintains a long service life and best choice for wood veneer, cabinet doors, furniture & suitable for all kinds of decorative surfaces.

Model: WP40TM / WP4 0TM / ACROBAT 200

Technical Specification

| Model | WP2 0TM | WP4 0TM | ACROBAT 200 |

|---|---|---|---|

| Table | 1400x2400 / 1400x3000 | 1400x2400 / 1400x1200 / 1400x3000 | 1400x3000 / 1400x3000 |

| Turbine | 190v 600 W 620 mm3R | 190v 600 W 620 mm3R | 190v 600 W 620 mm R |

| Vacuum System | 100 m3/Hour | 100 m3/Hour | 100 m3/Hour |

| Heat Measurement Sensor | Infrared Heat Sensor | Infrared Heat Sensor | Infrared Heat Sensor |

| Pvc Loading Unit | Special Design | Special Design | Special Design |

| Molding System | Manuel Special Design | Manuel Special Design | Manuel Special Design |

| Fail Detection System | Audible and Visual | Audible and Visual | Audible and Visual |

| Operator Panel | Touch Panel 7 Inches | Touch Panel 7 Inches | Touch Panel 7 Inches |

| Electrical and Electronical Equipment | Professional | Professional | Professional |

| Moving Motor | 0.37 Kw 1 / 15 S40 | 0.37 Kw 1 / 15 S40 | 0.37 Kw 1 / 15 S40 |

| Operator Time | 3-4 Minute | 3-4 Minute | 3-4 Minute |

| Weight | 1450 Kg | 1450 Kg | 2150 Kg |

| Total Enery Consumption | 8 Bar 30 Kw | 8 Bar 30 Kw | 8 Bar 30 Kw |

About the Machine

The powerful stable & reliable vacuum membrane press system achieves higher vacuum pressure of about 100m³ per hour and works on low power consumption. It has the capacity to work quick, continuous powerful air evacuation, very strong pressure effect and applies equal force on the pressing surface.

The temperature is controlled by an infrared heat sensor, manages the heat perfectly and helps for pre-setting the material according to the different thicknesses. This vacuum membrane press has IR heating technology that produces high-quality warm to the material quickly which saves much energy and prepares the workpiece for processing.

The electrical & electronic equipment has high efficiency, spreads the heat evenly, firmly absorbs and results in a smooth surface. It improves convenience & productivity, encourages precise output and makes the operation more comfortable.

In a vacuum membrane press, the integrated moving motor used to realize the movement, produces less noise, stable operation and high performance. It operates with good efficiency, not affected by vibration or resonance issues, highly durable and has accurate control of motor speed.

The double sliding table unit slides towards the membrane frame for the press operation and offers easy access from all sides which is especially helpful when processing large complicated shapes. The work table is made of a high-strength material that is not easy to deform and greatly increases the functionality of the press.

The turbine is used to accelerate the cooling process, controls the temperate mode, cools the exhaust steam and smartly distributes the air. This optimized system is an effective steam ejector, prevents inlet attacks and assists the equipment to avoid problems.

The machine fail detection system identifies the fault that has occurred during the operation, pinpoints the errors to determine the quality and ensures the performance as expected. It plays an important role in the safety-critical process, avoids material wastage, minimizes the consequences and extends the lifetime of the machine.

Are You looking For Similar Products?

Request A Quote Now!

Please use this contact form to make an inquiry.

We will respond quickly to your valuable inquiry for clear understanding and offering services round the clock across various geographical locations!