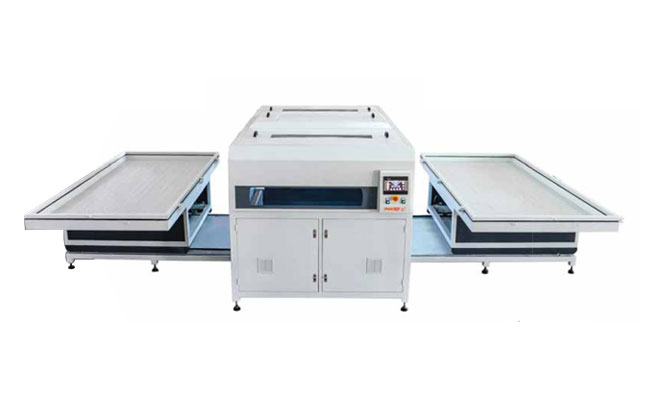

Edge Banding Machine

Edge Banding Machine

Edge Banding Machine

Gives The Finished Look & Protects The Wood

The edge banding machine provides perfect mechanical edge processing solutions with a fine finish, extreme accuracy and offers effective operation for banding & profile trimming. It is equipped with a precise gluing unit that melts to join with a wooden panel based on the accordance requirements. It offers optimum flexibility with extensive unit equipment, possible automation with no mess & fuss and able to do a large amount of work. The edge banding machine’s solid structure, compact design & sturdiness of working configuration guarantee flawless banding under any working condition to ensure superior edge appearance and deliver a quality result. This ultimate edging unit generates required production, maximum process reliability, reduced energy consumption and is highly efficient in terms of speed & cost.

Model: EB-220

Technical Specification

| Model | EB-220 |

|---|---|

| Thickness of roling edge-banding belt | 0.4-3mm |

| Height of roling edge-banding belt | 12-45mm |

| Workpiece thickness | 10-45mm |

| Air pressure | 0.6-0.8Mpa |

| Gross power | 6kw |

| Machine outline size | 2450 x 680 x 1280mm |

| Weight | 700kg |

About the Machine

The stable feeding belt has synchronous teeth & pinion that give smooth traction and vibration-free feeding with exceptional panel holding. It infeed the wood material exactly straight over the width, positioning properly to a conveyor and ensures continuous feeding.

The glue melts that help to seal the side of the panel, applied directly into the material to hold permanently with invisible joints, have optimum glue joint quality and adapt seamless performance. The banding unit can band the edges of workpiece thickness up to 45mm and edge cutting unit process without edge protrusion.

The end cutting unit operates to precisely cuts the unwanted banding material on the front & rear sides. The buffing process provides the polishing effect to the material surface edges for maximum gloss, complete finishing and results in an excellent long-lasting quality finish without the need for any subsequent work.

In the edge banding machine, the standard reliable edge trimmer removes the excess edge automatically on both the front & rear end of the panel by linear guides. A fully adaptive trimming blade matches the required thickness & height uniformly even at high feed rates and high-frequency motors ensure the best top & bottom edge finish.

The innovative Delta easy touch control panel allows for intuitive operation and a user-friendly set-up procedure. It has an individual unit selection for the setting of tool corrections, controls the machining functions according to the working program selected and reduces the risk of a misaligning process to zero.

Request A Quote Now!

Please use this contact form to make an inquiry.

We will respond quickly to your valuable inquiry for clear understanding and offering services round the clock across various geographical locations!