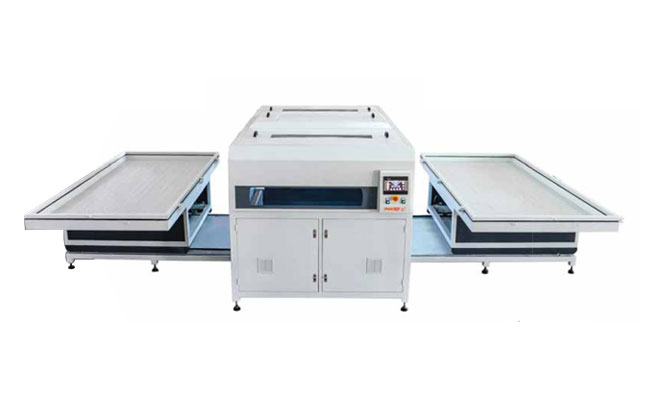

Thicknesser Planer Machine

Thicknesser Moto

Thicknesser Moto

Removes Residue To Enhance The Surface

Our thicknesser planer machine is designed with a single table that can be mechanically raised & lower down to remove the wood to produce uniform thickness & width, provides a high-quality surface finish and can accommodate the different material sizes. After the board is positioned, it rests perfectly on the sliding table to start the operation and allows the blades to cut with the grain. It is sizing the desired thickness and creates a smooth surface parallel to each other as first-class finishing standards. It guarantees perfect results with excellent ease of use and reliability in professional usage. The highest level of strength, stability and has been optimized for powerful performance. It has innovative controls and operates the machine with heavy precision components for maximum durability.

Model: Moto 350

Technical Specification

| Thicknessing Machine | Unit | MOTO 530 |

|---|---|---|

| Max. working width | mm | 530 |

| Cutterblockk diameter | mm | 120 |

| Max. cutting depth | mm | 8 |

| Feed speed | MT/1' | 5-.20 |

| Max working height | mm | 300 |

| Number of knives | p-mm | 4p-30*530*3 |

| Cutterblock rotation speed | g/1' | 4800 |

| 3-phase Motor power | HP (KW) | 7.5 (5.5KW) |

| Power Of the Motorgear for rise/fall | HP (KW) | 0.5 (0.33KW) |

| Feeder motor power | HP (KW) | 1.0 (0.75) |

| Work table dimensions | mm | 1050 x 532 |

| Min. working lenght | mm | 280 |

| Net weight | kg | 810 |

| Sound power level at operator's site | db | 82.2 |

| Thicknessing Machine | Unit | MOTO 530 |

|---|---|---|

Standard Accessories | ||

| Knife-setting device | -- | * |

| 4 pcs planing knives | -- | * |

| Motorized thicknesing table lifting | -- | * |

| Sectioned feeding roller | -- | * |

Optional Accessories | ||

| 1 Table roller | -- | -- |

| 2 Table rollers | -- | -- |

| Motor | HP (KW) | 103.0 (7.5KW) |

| Control electroninstallations and quota volocita | MT/1' | * |

| Feeding rollers rubber output | -- | * |

| Sectioned feeding roller | -- | * |

About the Machine

A thicknesser planer machine is equipped with motorized thicknesser table lifting for the adjustment based on the material thickness to meet the demands of different industries. Also, the table is made up of cast iron and has 4 heavy pillar supports. It assists in and outfeed rollers to perform the smooth transportation in any working condition.

The cutterblock provides an excellent thickness planing result, helps to aim for gentle & careful material processing and completely precise dimension quality. The knife setting device checks the level of the knife which is selected for the operation and various options are available to choose from based on the material.

The sectioned feeding roller device helps for the flexible linear feeding in the process of in & out, increases the range of motion and evenly feeds on the table without any damage to the material & its edges. A thicknesser planer machine has 4 planing knives for the best finish, maximum speed production and used for clean & accurate cuts.

The three phase motor has the power to drive the machine, has uniform transmission, gives longer service life and has high repeat accuracy & direction control. It has ultimate flexibility and ability for dynamic performance that can change to various speed & load requirements.

The depth scale is of particular importance making it easier to confirm the thickness of the material being processed for the output. It is highly useful to operate workpieces with varying thicknesses. The dust extraction outlet collects the sawdust, ensures a clean operation, leads to better product quality and improves health safety.

Request A Quote Now!

Please use this contact form to make an inquiry.

We will respond quickly to your valuable inquiry for clear understanding and offering services round the clock across various geographical locations!