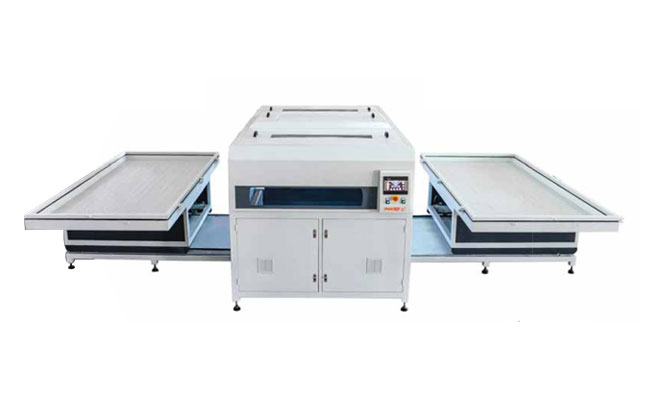

Veneer Stitching Machine

Veneer Stitching Machine

Veneer Stitching Machine

Makes The Small Veneer Into One Piece

Our veneer stitching machine joins the two veneer sheets in different sizes as one piece by using glue. It is widely used in the furniture & plywood industry. It has the characteristics of simple operation, low noise and highly preferred due to its ability to create a fine veneer finish on a wide range of goods. This stitching machine is flat, firm, greatly improves material utilization, reduces material costs and the ideal choice for woodworking to increase the economic benefits.

It supports the thickness of the veneer up to 2 mm and speed of feeding the workpiece is 9m per minute for easy operation. Enables the industry to accurately bond with no visible joint line.

Model: GAF-650

Technical Specification

| Model | GAF-650 |

|---|---|

| Arm Length | 650mm |

| Power Required | 0.25KW |

| Veneer Thickness | 0.4-2mm |

| Dims | 860 x 320 x 450 |

| Feed Speed | 9m/min |

About the Machine

It makes the narrower stitch to the wider veneer in seconds by using thermo adhesive glue thread, seamless paste stitching the material without gaps and cutting the glue thread automatically after finishing the process.

With the help of hot air gluing, it is possible to come up with seamlessly joined veneers producing high-end stitching that delivers smooth gluing for the best results. It gives prominence to the stable quality, avoids the glue blocking in the heating pipe and has a longer service life.

Before using the thread, it is heated by electric resistance which ensures the tight stitching and bond the material through the melting glue line. It improves the production efficiency, seam very quickly and covers every need of veneer joint processing.

Request A Quote Now!

Please use this contact form to make an inquiry.

We will respond quickly to your valuable inquiry for clear understanding and offering services round the clock across various geographical locations!