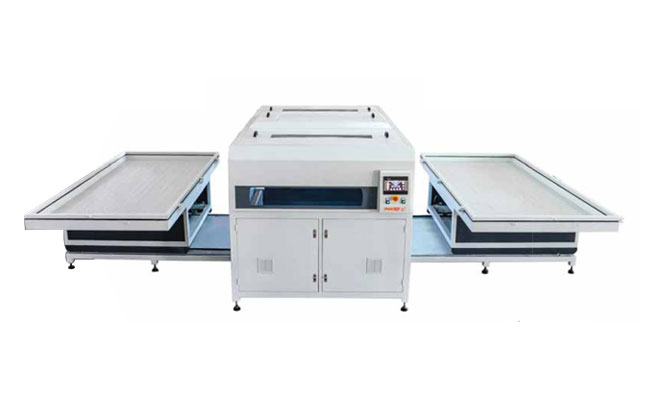

Two Head Boring Machine

Two Head Boring Machine

Two Head Boring Machine

Sturdily Built To Execute Holes In A Line

The highly automatic two head boring machine is a new generation range of premium drilling solutions that can drill the material on both horizontal & vertical sides with required parameters. The machine body incorporates a heavy-duty structural design that prolongs the machine’s life and undergoes heat treatment to keep the operation never deformed. Built for extreme hole drilling performance and has high-quality drill row, linear guides, electrical & pneumatic components. It has been designed to meet the most complex demands in hole-making with maximum versatility that can operate vertically & horizontally and easily switch over from one process to another. It works in tight spaces that are difficult to access, precise drill feed, suitable for long-time drilling without machine overload and reduced incorrect operation risk.

Model: MZ73212A

Technical Specification

| Model | MZ73212A |

|---|---|

| Maximum Diameter Of Holes | 35mm |

| Depth Of Drilled Holes | 0-60mm |

| Number Of Spindles | 21x2rows |

| Center Distence Between Spindles | 32mm |

| Two Rows Drilling Diatance | 330-1400mm |

| Rotation Of Spindle | 2840r/min |

| Total Motor Power | 1.5kw |

| Air Pressure | 0.5-0.8mpa |

| Weight Of The Whole Machine | 500kg |

| Packing Size | 2400 x 1200 x 1500mm |

About the Machine

The drilling head is present vertically & horizontally and can set the required axial distance to drill the panel according to the demands. A two head boring machine is having two rows of 21 drilling shafts that can be adjusted to meet the output specification.

The guide rail directs the drill to a straight motion path, highly sturdy, self-aligning and prevents material from moving up or down or derailment. The simple operating system is available to work for the horizontal & vertical drill on the top. Easy functioning to run, correct the measurement and stop the operation.

The powerful motor drives the operation from the pulley to the spindle, allows different speeds with adequate control to ensure the perfect drill holes, highly durable and mainly improves the operational efficiency.

The heavy-duty working table is employed to achieve extremely precise positioning, good rigidity and avoid deformation. It is quick to use and convenient to process the needs of different workpieces.

In a two head boring machine, the spindle has a speed of about 2840rpm, exhibits high accuracy processing, rotates the drill bits, has stable cutting performance, wide speed range, labor saving and improves the degree of automation.

The workpiece is clamped by a pneumatic clamp with a large force for reliable holding. Instructing the drilling measure units and enables simple, fast & adjustable parameters. Also, can adjust the table according to the processing.

Request A Quote Now!

Please use this contact form to make an inquiry.

We will respond quickly to your valuable inquiry for clear understanding and offering services round the clock across various geographical locations!