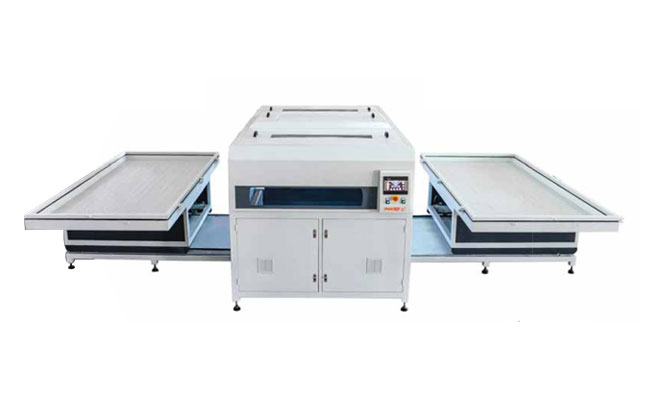

CNC Wood Router

CNC Wood Router

CNC Wood Router

Turns Raw Material Into Final Products

The automatic computer numeric control CNC wood router is used to cut various materials such as acrylic, plastic, MDF & wood etc and reduces the man-hours required to produce precise and professionally done outputs. It is well known for its versatility, ability to process effectively, achieves maximum precision by eliminating errors, increases both the quantity & quality and lowering material wastage. It involves several materials in various parts of sizes & shapes, improves operational efficiency and capable of processing quickly large and thick materials. A CNC wood router gives a significant impact on the overall profitability, advanced computerized programming and the ability to replicate the same design more times.

Model: MW1325 / MW1530

Technical Specification

| Model | MW-1352 | MW-1530 |

|---|---|---|

| Spindle | HSD 6 HP ER32 | HSD 6 HP ER32 |

| Inverter | iBESTCH | iBESTCH |

| Max. Width | 1270mm | 1500mm |

| Max. Length | 2540mm | 3000mm |

| Z Clearance | 150 mm (Max.) | 150 mm (Max.) |

| Table | T-Slot | T-Slot |

| ATC | Optional | Optional |

| Controller | Nk105 controller | Nk105 controller |

| Max. Weight | 80 Kg / sqm on bearings | 80 Kg / sqm on bearings |

| Cutting Material | Acrylic, Plastic, MDF, Aluminum, Wood, Brass, Copper | Acrylic, Plastic, MDF, Aluminum, Wood, Brass, Copper |

| Axis | 4 | 4 |

| Spindle Speed | 18000 rpm | 18000 rpm |

| Spindle Cooler | Fan / Air Cooled | Fan / Air Cooled |

| Speed | 20 - 30 m/min | 20 - 30 m/min |

| Axis Motor | Stepper motor and small electrical case | Stepper motor and small electrical case |

| Brush Feet | Yes | Yes |

| Dust Cover | Yes | Yes |

| Print Interface | USB 2.0 + Networking | USB 2.0 + Networking |

| Power Specification | AC 220 V 4.5KW | AC 220 V 4.5KW |

| Operational Environment | Temperature: 20°C - 30°C Humidly: 20% to 80% | Temperature: 20°C - 30°C Humidly: 20% to 80% |

| Software | ArtCAM / EnRoute / Type 3 | ArtCAM / EnRoute / Type 3 |

| Dimension & Weight Machine | L3765 x W1760 x H220mm 1.5 Ton | L3765 x W1760 x H220mm 1.5 Ton |

| Dimension & Weight Package | L3900 x W1900 x H1350mm 1.6 Ton | L3900 x W1900 x H1350mm 1.6 Ton |

About the Machine

The heavy-duty gantry is floating on the T-slot / vacuum bed working table to cut the material accurately by using the spindles. It reduces the impact of vibration on the output, increased flexibility and produces stable processing without deformation to be out of shape.

The helical rack & pinion ensures high precision by providing the exact position for the function, it keeps the operation in the linear motion from the rotational movement on the rack for the good end-product, assists smoother gear operation and reduces the noise & vibration during processing.

In a CNC wood router, the CAD/CAM software provides the set of design instruction to the machine, converts them to machine language, sends them to the controller to initiate the processing, reduces expense & waste production and transforms the command components into finished products.

The hybrid servo motor drives the machine perfectly in speed & angle of rotation and produces torque at high speed. It converts the signal received from the CNC device and converts that to the movement of the spindle and determines the processing accuracy & surface quality.

The CNC wood router has bearing guide rail maintains the alignment & straight sliding in the linear motion, supports carrying heavy loads and reduces the friction of moving parts. It protects from deformation, offers exceptional rigidity, acts as a resistance to external influence and runs extremely quiet.

The spindle runs at the speed of about 24000 rpm with the help of a hybrid servo motor, increases the potential of the machine, rotates the axis and gives high-performing engraving, drilling, milling & so on. It is equipped with an adequate fan/air cooled spindle cooler to avoid damage and produce a fine surface finish.

The EZ controller is easy to operate, instructs the cutting requirements of the material and enables to do the precise & fast cutting pattern that results in a high volume of production. It takes the responsibility of executing the command by sending an electronic signal to the motor for the proper operation.

Request A Quote Now!

Please use this contact form to make an inquiry.

We will respond quickly to your valuable inquiry for clear understanding and offering services round the clock across various geographical locations!