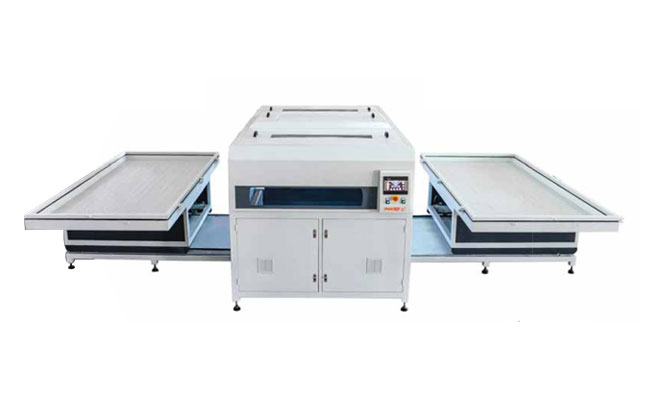

Vacuum Press Machine

Vacuum Press Machine

Vacuum Press Machine

Using Various Types Of Veneer Panels

Our vacuum press machine uses a membrane fitted with a frame that is attached to the rigid vacuum bed to make the required shape. It applies vacuum by using vacuum pumps and the maximum output is achievable by required pressing power. The overpressure is generated with air on all the sides of the workpiece which is suitable for mold processing. This membrane forming press is designed as an ideal working process to get the shaped panels for the materials such as bendy plywood, plywood, thick sawn veneer, MDF etc. Vacuum press machine takes very low energy consumption, eliminates the high costs, has quick & easy access, characterized by high strength, elasticity & transparency and brings a new level of speed & convenience to the vacuuming operation.

Model: Vacuum Press

Technical Specification

| Model | VP-1330 |

|---|---|

MACHINE CONSTRUCTION | |

| Overall dimensions: | approx. 3400 x 1750 x 1100 mm |

| Dimensions inside the frame: | approx. 2880 x 1280 mm |

NATURAL RUBBER MEMBRANE | |

| Material: | natural rubber NR |

| Dimensions: | 3100 x 1500 x 2 mm |

| Heat resistance: | up to + 130 °C |

| Elongation at tear: | 600% |

| Material hardness: | 40 Shore-A |

| Colour: | grey |

SILICONE MEMBRANE ECONOMY | |

| Material: | Silicone |

| Dimensions: | 3100 x 1500 x 2 mm |

| Heat Resistance: | up to + 230 °C |

| Elongation at tear: | 700% |

| Material Hardness: | 40 Shore-A |

| Colour: | white/transparent |

SILICONE MEMBRANE HIGH-PERFORMANCE | |

| Material: | silicone |

| Dimensions: | 3100 x 1500 x 2 mm |

SILICONE MEMBRANE HIGH-PERFORMANCE | |

| Heat resistance: | up to + 230 °C |

| Elongation at tear: | 700% |

| Material hardness: | 40 Shore-A |

| Colour: | Transparent |

MEMBRANE FAST-CHANGE SYSTEM, EVERY MEMBRANE IS SUITABLE, INCL. FIXING BOLTS & PROFILES, PHENOLIC RESIN WORKING SURFACE | |

| Material: | Phenolic resin laminated plywood |

| Heat resistance: | up to + 160 °C |

| Suction points: | up to 70 |

25 M³ HIGH-PERFORMANCE VACUUM PUMP | |

| Type: | Dry running rotary vane pump |

| Air suction speed: | 25 m³/h |

| Pressure: | up to 9 t/m² |

40 m³ high-performance vacuum pump | |

| Type: | Dry running rotary vane pump |

| Air suction speed: | 40 m³/h |

| Pressure: | up to 9 t/m |

80 M³ HIGH-PERFORMANCE VACUUM PUMP | |

| Type: | Dry running rotary vane pump |

80 M³ HIGH-PERFORMANCE VACUUM PUMP | |

| Air suction speed 80 m³/h | Air suction speed 80 m³/h |

| Pressure: | up to 9 t/m² |

CONTROL UNIT (VERTICAL OPENING) | |

| Pressure monitoring: | analogue vacuum pressure gauge |

| Temperature control: | digital |

| Heating time control: | digital |

VACUUM PRESSURE CONTROL: MECHANICAL VACUUM PRESSURE REGULATOR | |

| Control range of vacuum pressure: | 200 - 900 mbar rel. |

DIGITAL FESTO VACUUM PRESSURE CONTROL | |

| Control range of vacuum pressure: | Precisely 20 - 900 mbar rel. (variable) incl. 200 l vacuum tank |

VERTICAL OPENING MECHANISM | |

| Type: | pneumatic |

| Pneumatic cylinder: | 4 pcs. |

| two-hand safety operation | two-hand safety operation |

| Overall dimensions: | approx. 4000 x 2000 x 1800/2400 mm |

| Stroke: | approx. 650 mm |

HEATING DRAWER | |

| Usable area: | approx. 2600 x 1200 mm |

| Material thickness: | 0 - 70 mm |

| Heating power of the CHS heating system: | 16 kW | 400 V | 50/60 Hz |

| Circulating hot air fans: | 2 pcs. |

| Electronic temperature control: | up to + 230 °C |

| Pull-out working surface with grating: | 30 x 30 mm |

PERFORATED STAINLESS STEEL SHEET | |

| Perforation: | 5 mm |

| OVERALL DIMENSIONS: | APPROX. 2000 X 1000 X 2 MM |

About the Machine

A vacuum press machine is equipped with both a thermo heating unit that is used to heat the workpiece and forming unit is exclusively designed to press the material with a vacuum pump for creating the necessary vacuum. This machine provides a more convenient solution and works for both the thermoforming & vacuum forming in a single machine. The transparent silicone membrane is designed primarily for pressing even heavy-duty material with the standard membrane.

In a thermo heating system, the vacuum press machine is using circulating air system which allows to pre-heat the material for the pressing process which is particularly helpful for the hard shapes. It has electronic temperature control, exact temperature distribution over the surface of a workpiece, contains overheating protection to avoid damage and offers more energy saving by giving lower power input.

After the completion of the heating procedure, the material can be placed on the former to make the shape. The gas spring gives support for the membrane frame, provides convenient access and assists to open & close easily. It applies the pressure evenly throughout the panel, has a regulator to control the pressure with variable pressure settings and a rotary vane vacuum pump to create various shapes, sizes or thicknesses of the workpiece.

It is space-saving with two equipment together, has a possibility to work with the material for designing a different kind of new forms or shapes and fulfills the demands of the industry.

Request A Quote Now!

Please use this contact form to make an inquiry.

We will respond quickly to your valuable inquiry for clear understanding and offering services round the clock across various geographical locations!