Combined Wood Cutting Machine

Combined Wood Cutting Machine

Combined Wood Cutting Machine

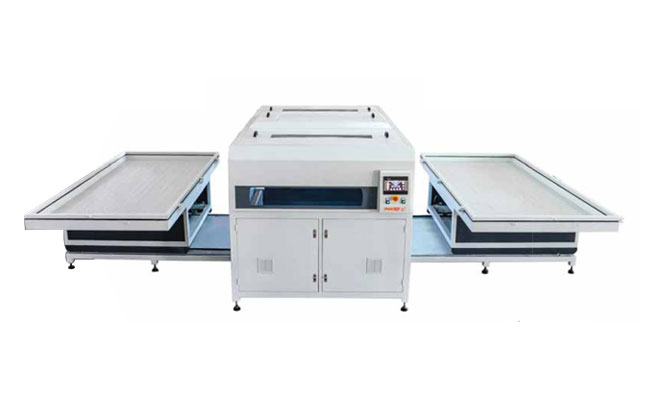

5 Functions C400

Our 5 functions C400 is the multi-function wood cutting machine that performs a diverse range of tasks such as woodcutting, carving and shaping. It is easy & convenient to use the combined wood cutting machine that has several tools and functions within the smaller compact single unit such as ripping or crosscutting, squaring, precise dimensioning of solid wood, hole & slot and for moulding & tenoning. This allows the woodworker to perform several different types of the machine works in an individual machine, effective workflow of different operations, easy switch of one function to another because it’s configurable in one single unit that takes up less room thus space-saving.

Model: C400

Technical Specification

| Planer | Unit | C400 |

|---|---|---|

| Working tables | mm | 400x1800 |

| Cutterblock diameter | mm | 70 |

| Cutterblock rotation speed | r.p.m | 5700 |

| N. of knives | n° | 3 |

| knives dimensions | mm | 400x20x3 (400x25x3) |

| Max table adjustement | mm | 4 |

Thicknesser | Unit | C400 |

| Working table | mm | 400x760 |

| Feed speed | m/1' | 7 |

| Max. working height | mm | 220 |

| Min. working height | mm | 4 |

| Cutterblock rotation speed | r.p.m. | 5700 |

| Max. cutting depth | mm | 4 |

Mortiser | Unit | C400 |

| Working table | mm | 250x500 |

| Longitudinal stroke | mm | 205 |

| Trasversal stroke | mm | 95 |

| Vertical stroke | mm | 90 |

| Churck | mm | 16 |

| Churck rotation speed | r.p.m. | 5700 |

Circular saw | Unit | C400 |

| Working table | mm | 326x1112 |

| Shaft rotation speed | r.p.m. | 4500 |

| Blade diameter | mm | 300 |

| Blade bora diameter | mm | 30 |

| Cutting height 90° | mm | 100 |

| Max. distance between blade and fence | mm | 730 |

| Blade inclination | 0° | 45° |

| Max cutting height 45° | mm | 50 |

| Shaft rotation speed engraver | r.p.m. | 7000 |

| Engraver blade diameter | mm | 90 |

| Engraver blade bora diameter | mm | 22 |

Shaper | Unit | C400 |

| Working tables | mm | 326x1112 |

| Shaft rotation speeds | r.p.m. | 2000/3100/4400/7000 |

| Standard shaft diameter | mm | 30 |

| Spindle lenght | mm | 105 |

| Shaft vertical stroke | mm | 115 |

| Max. tool diameter | mm | 180 |

| Max. tenoning depth | mm | 65 |

Tenoning Carriage | Unit | C400 |

| Carriage dimensions | mm | 1800x315 |

| Carriage stroke | mm | 1800/2200 |

Standard Accessories | Unit | C400 |

| N°2 clamp lever | - | * |

| Sharper fence | - | * |

| Service wrenches | - | * |

| Mortiser chuck | - | * |

| Table extensions with swinging arms | mm | 860x600 |

| Guards on mortiseur chuck | - | * |

| 3 pcs. planing knives | - | * |

| Planer guide | - | - |

| Saw guide | - | - |

| Bridge sefety hood on planer | - | * |

| 3-phase motor power | HP - KW | 4,0 - 3,0 |

| Weight | kg | 645 |

Optional Accessories | Unit | C400 |

| Single-phase motor | HP - KW | 4,0 - 3,0 |

| Increasing 3-phase motor | HP - KW | 5,5 - 4,0 |

| Set of wheels with feeding steering bar | - | * |

| Wescott(Diameter) | mm | 16 |

| Carriage stroke | mm | 2200/2200 |

| Carriage stroke | mm | 2600/2600 |

| Tenoning with protection shelf |

Technical Specification

| Planer | Unit | C400 |

|---|---|---|

| Working tables | mm | 400x1800 |

| Cutterblock diameter | mm | 70 |

| Cutterblock rotation speed | r.p.m | 5700 |

| N. of knives | n° | 3 |

| knives dimensions | mm | 400 x 20 x 3 (400 x 25 x3) |

| Max table adjustement | mm | 4 |

| Thicknesser | Unit | C400 |

| Working table | mm | 400x760 |

| Feed speed | m/1' | 7 |

| Max. working height | mm | 220 |

| Min. working height | mm | 4 |

| Cutterblock rotation speed | r.p.m. | 5700 |

| Max. cutting depth | mm | 4 |

| Mortiser | Unit | C400 |

| Working table | mm | 250x500 |

| Longitudinal stroke | mm | 205 |

| Trasversal stroke | mm | 95 |

| Vertical stroke | mm | 90 |

| Churck | mm | 16 |

| Churck rotation speed | r.p.m. | 5700 |

Circular saw | Unit | C400 |

| Working table | mm | 326x1112 |

| Shaft rotation speed | r.p.m. | 4500 |

| Blade diameter | mm | 300 |

| Blade bora diameter | mm | 30 |

| Cutting height 90° | mm | 100 |

| Max. distance between blade and fence | mm | 730 |

| Blade inclination | 0° | 45° |

| Max cutting height 45° | mm | 50 |

| Shaft rotation speed engraver | r.p.m. | 7000 |

| Engraver blade diameter | mm | 90 |

| Engraver blade bora diameter | mm | 22 |

Shaper | Unit | C400 |

| Working tables | mm | 326x1112 |

| Shaft rotation speeds | r.p.m. | 2000/3100/4400/7000 |

| Standard shaft diameter | mm | 30 |

| Spindle lenght | mm | 105 |

| Shaft vertical stroke | mm | 115 |

| Max. tool diameter | mm | 180 |

| Max. tenoning depth | mm | 65 |

Tenoning Carriage | Unit | C400 |

| Carriage dimensions | mm | 1800x315 |

| Carriage stroke | mm | 1800/2200 |

Standard Accessories | Unit | C400 |

| N°2 clamp lever | - | * |

| Sharper fence | - | * |

| Service wrenches | - | * |

| Mortiser chuck | - | * |

| Table extensions with swinging arms | mm | 860x600 |

| Guards on mortiseur chuck | - | * |

| 3 pcs. planing knives | - | * |

| Planer guide | - | - |

| Saw guide | - | - |

| Bridge sefety hood on planer | - | * |

| 3-phase motor power | HP - KW | 4,0 - 3,0 |

| Weight | kg | 645 |

Optional Accessories | Unit | C400 |

| Single-phase motor | HP - KW | 4,0 - 3,0 |

| Increasing 3-phase motor | HP - KW | 5,5 - 4,0 |

| Set of wheels with feeding steering bar | - | * |

| Wescott(Diameter) | mm | 16 |

| Carriage stroke | mm | 2200/2200 |

| Carriage stroke | mm | 2600/2600 |

About the Machine

The high-strength aluminum sliding table ensures smooth operation, provides stability, accuracy, extreme robustness with a high-quality guiding system to get the precise cut and top-quality product in every job requirement.

The rip fence is the guide ruler that provides support for the workpiece which has placed parallel to the saw blade. A micro-adjustment system is used to set the measurements for the cut at a specific angle. The crosscut fence enabled to perform the cutting operation at any angle especially the miter cut by adjusting the angle of the fence. It prevents sizing errors and makes the material fit exactly without any slip from the saw blade using the flipstop tool.

In the panel saw unit, the main saw blade offers the cutting of solid wood quickly and gives smooth edges even for the hardest one. The scoring blade is an additional blade located in front of the main blade that hits the material first, provides a clear cut on the bottom side. It scores the material edges which are easy for the main blade to cut and gives splinter-free operation. The riving knife separates the material into two pieces, prevents blade pinching and protects the wood piece from any kickbacks.

The spindle moulders with tenoning carriage are used for rabbeting, moulding, shaping, basic tenoning of wood by providing equal pressure on the workpiece using the working table and also used to set the cutting angles with a robust micro-adjust system. The movement of height & angle can be adjusted by digital readouts to the maximum height of 105mm above the table.

In multi-function woodworking machine, thicknesser is used to reduce & maintain the uniform thickness of a wooden strip in its entire length and get the workpiece done with similar dimensions. Before this process, the sides of the wood must be flat faces and must be square-edged by the surface planer to rest the piece on the sliding table perfectly.

Mortiser is the operation of making squared, rectangular or circular holes in the wood to receive the tenon joint, made it possible with a powerful motor that moves the chisel and clamp which handles the position at a specific angle.

Request A Quote Now!

Please use this contact form to make an inquiry.

We will respond quickly to your valuable inquiry for clear understanding and offering services round the clock across various geographical locations!