Combined Wood Cutting Machine

Combined Wood Cutting Machine

Combined Wood Cutting Machine

2 Functions 400B

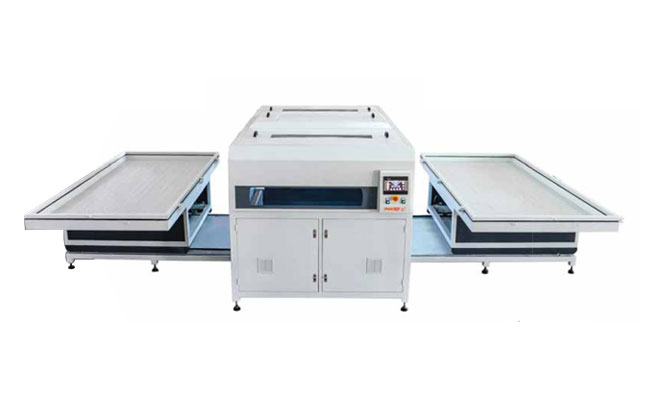

Our combined wood cutting machine has been developed with the extended functions of a panel saw and shaper. This standard machine is specifically designed with features of the sliding table, rip fence and crosscut fence. Also, equipped with three-phase motor power, a control panel for the angle adjustment that accurately gives the value digitally, a large stable ruler and a blade guard for the safety of operators from sharp blades. It is a completely reliable process to cut the wood materials by using the blades, intended to get the shapes such as rip cuts, cross cuts & miter cuts and tailor-made machining solution.

Model: 400B

Technical Specification

| Circular Saw | Unit | 400B |

|---|---|---|

| Working table | mm | 326x1112 |

| Shaft rotation speed | r.p.m. | 4500 |

| Blade diameter | mm | 300 |

| Blade bora diameter | mm | 30 |

| Cutting height 90° | mm | 100 |

| Max. distance between blade and fence | mm | 730 |

| Blade inclination | 0° | 45° |

| Max cutting height 45° | mm | 50 |

| Shaft rotation speed engraver | r.p.m. | 7000 |

| Engraver blade diameter | mm | 90 |

| Engraver blade bora diameter | mm | 22 |

Shaper | Unit | 400B |

| Working tables | mm | 326x1112 |

| Shaft rotation speeds | r.p.m. | 2000/3100/4400/7000 |

| Standard shaft diameter | mm | 30 |

| Spindle lenght | mm | 105 |

| Shaft vertical stroke | mm | 115 |

| Max. tool diameter | mm | 180 |

| Max. tenoning depth | mm | 65 |

Tenoning Carriage | Unit | 400B |

| Carriage dimensions | mm | 1800x315 |

| Carriage stroke | mm | 1800/2200 |

| Standard Accessories | Unit | 400B |

| N°2 clamp lever | - | - |

| Sharper fence | - | - |

| Service wrenches | - | - |

| Table extensions with swinging arms | mm | 860x600 |

| Saw guide | - | - |

| 3-phase motor power | HP - KW | 4,0 - 3,0 |

| Weight | kg | 380 |

Standard Accessories | Unit | 400B |

| Single-phase motor | HP - KW | 4,0 - 3,0 |

| Increasing 3-phase motor | HP - KW | 5,5 - 4,0 |

| Contouring fence | - | - |

| Carriage stroke | mm | 2200/2200 |

| Carriage stroke | mm | 2600/2600 |

| Tenoning with protection shelf | - | - |

Technical Specification

| Circular Saw | Unit | 400B |

|---|---|---|

| Working table | mm | 326x1112 |

| Shaft rotation speed | r.p.m. | 4500 |

| Blade diameter | mm | 300 |

| Blade bora diameter | mm | 30 |

| Cutting height 90° | mm | 100 |

| Max. distance between blade and fence | mm | 730 |

| Blade inclination | 0° | 45° |

| Max cutting height 45° | mm | 50 |

| Shaft rotation speed engraver | r.p.m. | 7000 |

| Engraver blade diameter | mm | 90 |

| Engraver blade bora diameter | mm | 22 |

| Shaper | Unit | 400B |

|---|---|---|

| Working tables | mm | 326x1112 |

| Shaft rotation speeds | r.p.m. | 2000 / 3100 / 4400 / 7000 |

| Standard shaft diameter | mm | 30 |

| Spindle lenght | mm | 105 |

| Shaft vertical stroke | mm | 115 |

| Max. tool diameter | mm | 180 |

| Max. tenoning depth | mm | 65 |

| Tenoning Carriage | Unit | 400B |

| Carriage dimensions | mm | 1800x315 |

| Carriage stroke | mm | 1800/2200 |

Standard Accessories | Unit | 400B |

| N°2 clamp lever | - | - |

| Sharper fence | - | - |

| Service wrenches | - | - |

| Table extensions with swinging arms | mm | 860x600 |

| Saw guide | - | - |

| 3-phase motor power | HP - KW | 4,0 - 3,0 |

| Weight | kg | 380 |

Standard Accessories | Unit | 400B |

| Single-phase motor | HP - KW | 4,0 - 3,0 |

| Increasing 3-phase motor | HP - KW | 5,5 - 4,0 |

| Contouring fence | - | - |

| Carriage stroke | mm | 2200/2200 |

| Carriage stroke | mm | 2600/2600 |

| Tenoning with protection shelf | - | - |

About the Combined Wood Cutting Machine

In a multi-function woodworking machinery, the sliding table is made up of high-strength aluminum alloy material that helps to work without any deformation of a material and has tensional strength on an excellent push platform. It adopts the rigid frame structure design and ensures that the machine is running at a high degree of stability.

A rip fence is the straight edge guide rule that helps to place the workpiece parallel to the blade and sets the cutting measurements by a micro-adjustment system. It improves the cutting accuracy of a specific angle and reduces the chance of blade binding. The crosscut fence is attached to the sliding table, fixed with a miter scale for the required crosscut value and used to provide all angle cuts & miter cuts. The flipstop tool helps to support the wood from the slipping of a saw blade.

The main blade fulfills the purpose of cutting and sizing of materials, ultimately provides a smooth edge, a good finish for production by keeping the quality of blades for long life. The scoring blade works along with the main blade, used for chip-free cutting operation by marking a grooving in the materials. The riving knife is the protective feature that resists the kickback forces & blade pinching while the main blade is in process and cuts the workpiece into two pieces.

In combined woodworking machine, the spindle moulder is designed with a tilting spindle & tenoning carriage and measurements sets by a micro-adjustable fence. It is actively offering excellent quality of shaping, rabbeting, moulding, grooving and arch moulding etc. The useable spindle height above the table is 105mm, adjustment of height and angle is possible by digital LED display.

Request A Quote Now!

Please use this contact form to make an inquiry.

We will respond quickly to your valuable inquiry for clear understanding and offering services round the clock across various geographical locations!