Wood Cutting Machine

Wood Cutting Machine

Wood Cutting Machine

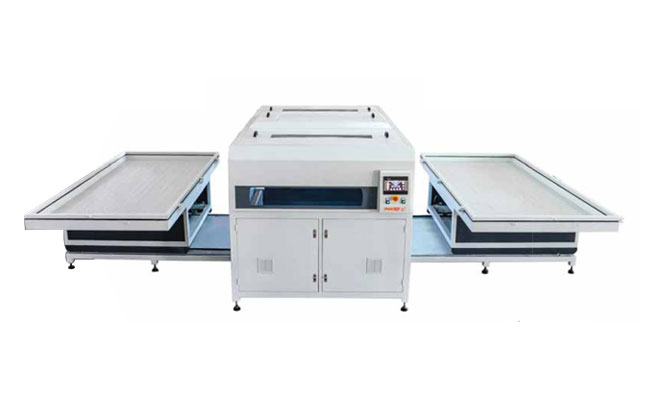

Panel Saw Sega 350

Our panel saw sega 350 designed with a saw blade is used to cut the wood materials into the needed required sized parts, shapes and sections. It fulfills the wood cutting requests, provides high cutting quality, is very sturdy and has excellent performance, It is an extremely flexible machine to satisfy the more demanding jobs in the market. It has developed to handle the most difficult tasks in woodworks, characterized by high-quality industrial machines and extreme accuracy in cutting throughout the process. This industrial series machine has loaded with better features that ensure that a large number of materials can be processed quickly for huge productive output. Table saw is affordable woodworking machinery, has reliable functionality, is durable, space-saving, precise in its operation and makes woodwork simple.

Model: SEGA350

Technical Specification

| Panel Saw | Unit | Sega350 |

|---|---|---|

| Blade diameter | mm | Φ350xΦ30 |

| Main blade speed | r.p.m. | 4000 |

| Scoring blade diameter | mm | Φ120xΦ20 |

| Scoring blade speed | mm | 8000 |

| Max depth of cut at 45° | mm | 92 |

| Max depth of cut at 90° | mm | 120 |

| Max rip capacity | mm | 1250 |

| Sliding beam size | mm | 3200x375 |

| Main table size | mm | 910x550 |

| Main extend table size | mm | 910x760 |

| Side extend table size | mm | 500x550 |

| Dust Extraction Outlet | mm | Φ120 |

| Main motor output | HP - KW | 7,5-5,5 |

| Scoring motor output | HP - KW | 1,0-0,75 |

| Net/Gross weight | kg | 610/710 |

| Machine packing size | mm | 2220×1030×1150 |

| Sliding table packing size | mm | 3560×420×210 |

Optional Accessories | Unit | Sega350 |

| Single-phase main motor | HP - kW | 4,0 - 3,0 |

| Single-phase scoring motor | HP - kW | 0,75 - 0,5 |

| Dimension Carriage 2800mm | mm | 2800x375 |

Technical Specification

| Panel Saw | Unit | Sega350 |

|---|---|---|

| Blade diameter | mm | Φ350xΦ30 |

| Main blade speed | r.p.m. | 4000 |

| Scoring blade diameter | mm | Φ120xΦ20 |

| Scoring blade speed | mm | 8000 |

| Max depth of cut at 45° | mm | 92 |

| Max depth of cut at 90° | mm | 120 |

| Max rip capacity | mm | 1250 |

| Sliding beam size | mm | 3200x375 |

| Main table size | mm | 910x550 |

| Main extend table size | mm | 910x760 |

| Side extend table size | mm | 500 x 550 |

| Dust Extraction Outlet | mm | Φ120 |

| Main motor output | HP - KW | 7,5-5,5 |

| Scoring motor output | HP - KW | 1,0-0,75 |

| Net/Gross weight | kg | 610/710 |

| Machine packing size | mm | 2220 ×1030 ×1150 |

| Sliding table packing size | mm | 3560 × 420 × 210 |

Optional Accessories | Unit | Sega350 |

| Single-phase main motor | HP - kW | 4,0 - 3,0 |

| Single-phase scoring motor | HP - kW | 0,75 - 0,5 |

| Dimension Carriage 2800mm | mm | 2800 x 375 |

About the Machine

Wood cutting machinery is equipped with a heavy-duty large aluminum sliding table that can withstand heavy load, high stability, ensures smooth operating motion, long life, provides extreme rigidity and minimum deflection. The precise guiding system helps to get a good straight line in the material while cutting and assures exact shapes like a cross, miter and format cuts.

A rip fence is a guide bar mounted on the right of the saw blade in the circular saw which is used to place the workpiece parallel and adjusts to the width of the saw blade for making the accurate cut at a specific angle. It provides a cutting guide by controlling the position of material that runs from front to top of the table and sets the required measurements with the help of a micro-adjustment system.

The crosscut fence in the circular saw is used to hold the workpiece perpendicular to the blade for angled cuts, repetitive cuts & miter cuts. Overall, it helps a lot for the accurate sawing of angles.

The main blade of wood cutting machinery offers high-quality sharpest material cut & shape. It is designed to fit in the entire cutting requirement and assures the exact need with a perfect match. The scoring blade is placed along with the main saw blade that rotates in an opposite direction to the main saw blade to avoid or stop the surface chipping by creating a groove in the material. The riving knife is an important safety feature as it separates the workpiece into two and prevents kickbacks when a material clamp on the main blade.

The dust collection system is disposing of the sawdust by extraction hoses connected with the panel saw that enables the suction process through the extraction pump to remove the dust sufficiently that occurred during the operation. It helps to avoid the dusty environment, improve the table saw workflow, keeps the machine running longer effectively and also gives safety for operators.

Request A Quote Now!

Please use this contact form to make an inquiry.

We will respond quickly to your valuable inquiry for clear understanding and offering services round the clock across various geographical locations!