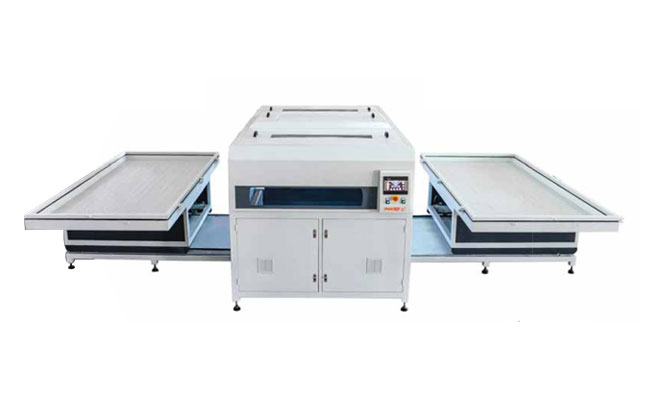

Surface Planer Machine

Surface planer

Surface planer

Generates A Sized Flat Wood Surface

The surface planer machine rapid 520 is the shaper that intends to produce the accurate plane & flat surface to the material for various purposes by a single point tool. It has capability to handle the machining for the heavy workpiece and gives the needed proper shape with parallel faces on all the sides. It overcomes the traditional handheld tooling method, consumes less time and accomplishes the shaping with precise measurement. A surface planer machine can quickly finish many boards to completely even edge & smooth surface and level the wood depending on the exact need. It is an important component of the woodworker’s professional life to achieve consistency all around the workpiece and makes the work more effective.

Model: RAPID 520

Technical Specification

| Model | RAPID 520 |

|---|---|

INDICATION AND CONTROL | |

| Control method | Manual |

CAPABILITY | |

| Max. cutting depth | 8mm |

WORKING TABLE | |

| Working table size | 2750mm x 520mm |

| Guide plate size | 1200mm x 190mm |

| Guide plate tilting angle | 0° / 45° |

TOOLS | |

| Planer cutterhead type | Straight |

| Diameter of planer cutterhead | 1200mm |

| Number of planer knives | 4pcs |

| Spindle speeds range | 5000rpm |

ENGINES AND POWER SUPPLY | |

| Spindle motor power | 5.5KW |

OVERALL DIMENSIONS AND WEIGHT | |

| Weight | 740kg |

| Overall length | 2750mm |

| Overall width | 860mm |

| Overall height | 800mm |

About the Machine

The working table supports the workpiece to flow properly along with the ways of the bed. After the material is fixed, clamps it with the bed & runs by means of the motor and it supports the other moving parts of the machine. It has an infeed table to keep the material & outfeed table to collect the output and in between the bridge guard is present to cover the block.

In a surface planer machine, the fence guides the workpiece to lay on the bed, makes the workpiece parallel to the blade and can change up to 45 degree bevel planing. The guard behind the fence provides a safe push platform. The bridge guard covers the workpiece, providing the protection for the uniform thickness & the width being processed and equipped with a knob for the adjustment.

The driving mechanism of the spindle motor is located under the table and the maximum spindle range is between 5000rpm. It gives greater power, rotates the shaft at high speeds, determines the force of processing, has high precision and shifts the operation fast.

The table height adjustment lever is available to fix the required height and protects from sizing errors. With the series of four knives in a block that ranging from small to large models to achieve the various industrial work. Also, it is designed with a dust hood to collect the dust suspended during operation and allows to work in a clean place without contaminants present.

Request A Quote Now!

Please use this contact form to make an inquiry.

We will respond quickly to your valuable inquiry for clear understanding and offering services round the clock across various geographical locations!