Automatic Sliding Table Saw

Automatic Sliding Table Saw

Automatic Sliding Table Saw

For The Classiest Woodworking Finish

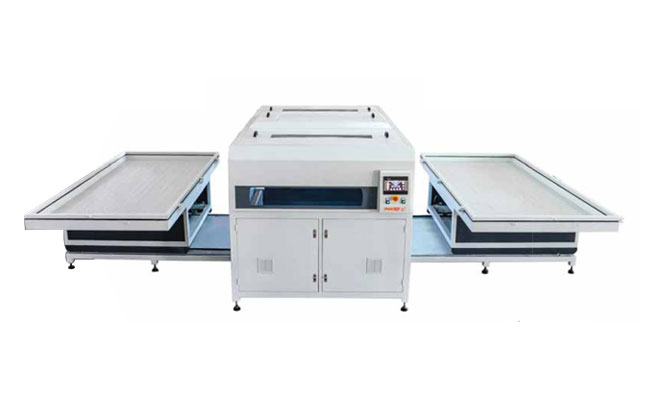

Our high-precision automatic sliding table saw is used to cut various kinds of wood based panels. It is widely used in the wood processing industry to meet the required output with production efficiency. This panel saw provides the safest, fastest and most accurate cutting function in a short amount of time with no deformation. It offers a less labor intensive solution that saves cost, produces a high volume of end products, has excellent repeatability across large production runs and makes the cutting profile more smooth & perfect. It has the ability to produce panels at a high rate of speed, eliminate waste pieces and protect against human error.

Model: MM400T

Technical Specification

| Model | MM400T |

|---|---|

| Dimension of sliding table | 3200x415mm |

| Gross cut capacity | 3200mm |

| Width of cut between saw blade and rip fence | 1250mm |

| Tilting saw group | 0-45° |

| Diameter of main saw blade | 400mm |

| Max cutting height 90° / 45° | 120mm |

| Speed of main saw spindle | 3000/4000/5000 r.p.m |

| Main saw motor power | 5.5 kw |

| Main spindle diameter | 30mm |

| Diameter of scoring saw blade | 120mm |

| Speed of scoring saw spindle | 8000 r.p.m |

| Scoring saw motor power | 1.1 kw |

| Scoring saw spindle diameter | 22mm |

| Gross weight | 1100 kgs |

| Overall dimension | 3250x3150x900mm |

About the Machine

In the automatic sliding table saw, a heavy-duty double layer 415mm aluminum sliding table supports the workpiece for stable operation, particularly on wide panels every time and guarantees a keen edge output. The main purpose of saw blade protection is to prevent the wooden panel from falling, the best safety feature for the operator to avoid accidents hence it is necessary for rip cuts. The dust collector outlet grabs all types of dust & debris and collects them to make the environment clean.

The control panel is designed for easy operation, can control the main & scoring blades lifting and fix the angles on the required side with a digital indicator. The enclosure’s independent electric box of automatic sliding table saw is perfectly connected with the machine to avoid frequent power failures that assist in more service life span.

The rip fence is a guideway that makes the wood keep parallel, has a micro-adjustment system to give the input measurements of the cutting angle. The cross slide table makes several varieties of processing such as repetitive cuts, miter cuts and angle cuts and has an eccentric locking clamp to avoid slippage.

The circular automatic main blade cuts the large wooden panel into required sized sections for the various materials such as density boards, particle board, artificial board, PVC board and solid wood board etc. The scoring blade is also present along with the main blade as a safety for the material, rotates in the opposite direction of the main blade to avoid wood surface damage and the riving knife safely makes the workpiece into two without kickbacks.

Are You looking For Similar Products?

Request A Quote Now!

Please use this contact form to make an inquiry.

We will respond quickly to your valuable inquiry for clear understanding and offering services round the clock across various geographical locations!